Across Europe, both businesses and public-sector operators face increasing pressure to demonstrate that they are lowering emissions, improving resource efficiency and protecting people. Environmental, social and governance (ESG) requirements are no longer optional: under the EU’s Corporate Sustainability Reporting Directive (CSRD), thousands of companies must begin disclosing detailed sustainability data from 2025. This creates new challenges for infrastructure owners that still rely on manual inspections, inconsistent data sources and siloed systems.

A powerful response is emerging: the combination of autonomous drones with digital-twin platforms capable of turning field data into rich 3D models and actionable, auditable insights.

Why ESG reporting needs better data

Traditional ESG reporting depends heavily on qualitative statements and infrequent site surveys. In sectors such as mining, research shows that digital twin technology can bridge the gap between ambitious ESG goals and the hard data needed to measure progress. Across dozens of case studies, digital twins delivered value at every project phase and helped improve multiple ESG factors, though successful deployment still requires the right skills and digital infrastructure.

Investors increasingly demand verifiable metrics, and regulators are tightening expectations. Without reliable, repeatable and quantitative data, organizations risk inaccurate reporting or even greenwashing claims. Digital twins offer an alternative: a consistent and transparent way to collect, validate and audit sustainability data.

Drones: the new data collectors

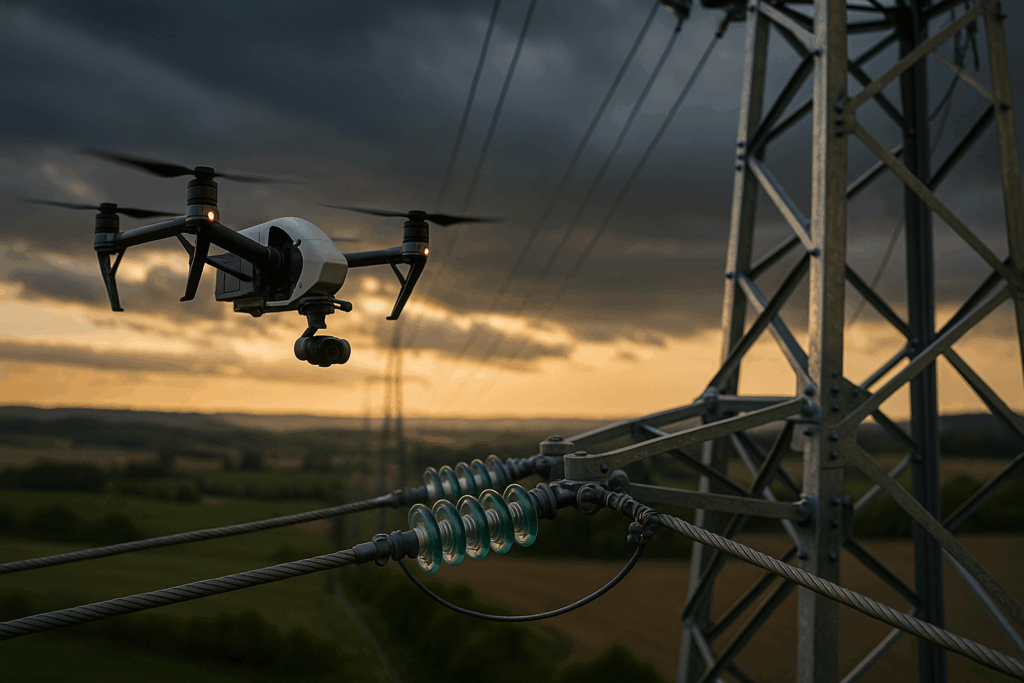

Autonomous drones can capture high-resolution imagery, LiDAR scans and thermal data across large or difficult-to-reach sites far more efficiently than manual crews. Multisensor drone payloads collect RGB, LiDAR and thermal data in a single flight, enabling accurate 3D models and reducing the need for hazardous site visits.

Case studies illustrate the impact. In one energy-sector deployment, drones inspected over 500 km of pipeline in a single day, cutting labour costs by more than 50%. For Europe’s five-million-kilometre electricity grid, long-range drones can automatically stabilise cameras on power-line towers, capturing images that reduce inspection costs by about one-third. Fully automated systems could eventually save up to 90% compared with helicopter surveys.

These methods eliminate emissions from crewed flights and deliver the rich, multimodal data needed to build accurate digital twins.

Building digital twins that matter

A digital twin is more than a 3D reconstruction – it is a continuously updated digital replica linked to real-world assets and conditions. Modern digital twins combine data from drones, sensors, IoT devices and AI to form dynamic models that support smarter operations.

Digital twins in commercial buildings have achieved up to 30% energy savings through optimised HVAC and lighting systems. AI-enhanced twins can detect anomalies early, extend asset life by 20–40%, reduce maintenance costs by up to 30%, and cut unplanned downtime by 30–50%.

At scale, the impact is substantial. Companies such as IKEA and Foxconn report roughly 30% reductions in energy use using digital-twin-powered optimisation. In industrial settings, twins deployed at Siemens and ABB facilities have lowered energy consumption by up to 20%.

Digital twins also enable granular carbon accounting, which is essential for CSRD compliance and broader ESG strategies. Studies highlight how digital twins can simulate alternative scenarios and identify the most sustainable choices. This is central to the EU’s Destination Earth programme, which uses a digital twin of the entire planet to support climate policy. Cities across Europe are adopting digital twins to improve urban planning, optimise layouts and reduce carbon footprints.

Integrating drones and digital twins for ESG excellence

Bringing drones and digital twins together unlocks a step change in ESG performance:

- Drones deliver the high-quality, multimodal data needed to build accurate digital twins.

- Digital twins transform drone data into real-time insights about energy use, equipment health and environmental impact.

- Operators can shift from annual inspections to continuous monitoring and data-driven decision-making.

This integration is transforming the energy sector. Long-range drones gather power-line data automatically, while digital-twin software analyses imagery to detect faults and schedule maintenance. This approach can save up to 90% compared with helicopter inspections, reduce wildfire risks and strengthen grid reliability.

In construction and oil & gas, drone-based digital twins improve safety, shorten inspections and support predictive maintenance – directly advancing ESG goals by cutting emissions, saving energy and protecting workers.

The European funding landscape

For companies looking to scale these technologies, Europe offers significant support. Horizon Europe funds innovations that advance both the digital and green transitions. The TwinEU initiative aims to create a pan-European digital-twin ecosystem for the energy system. Projects that integrate drones with digital twins to improve ESG reporting, carbon tracking or predictive maintenance align closely with EU priorities and are strong candidates for research and innovation grants.

Conclusion

Integrating drones with digital-twin technology is more than a technological trend, it is a practical path toward ESG excellence. Autonomous drones gather high-quality data efficiently and safely, digital twins convert that data into live operational intelligence, and together they help organizations cut emissions, save energy, reduce costs and demonstrate compliance with emerging EU standards. As Europe accelerates its digital and green transitions, organizations that adopt drone-powered digital twins will not only meet regulatory demands but also gain a competitive advantage in sustainability.

Predictive maintenance drones align with Europe’s climate and energy goals, saving around 10 kg of CO₂ per kilometre of power line inspected.

Robivon – Engineering Europe’s autonomous future