Walk onto any construction site today and you’ll notice the same pattern: fewer workers, tighter deadlines, and rising sustainability demands – Europe’s construction industry is under pressure. Labour shortages, an ageing workforce and productivity gaps have slowed building projects. At the same time, ambitious climate targets and the EU’s Built4People initiative demand cleaner, less disruptive and more resource‑efficient construction. To bridge this gap, Europe is investing heavily in autonomous construction robots and digital manufacturing tools that can build faster, safer and more sustainably. Innovations once considered experimental are now entering mainstream practice from 3D‑printed social housing to self‑driving construction vehicles, a new era of construction is quietly taking shape.

Why Europe Needs Construction Robotics

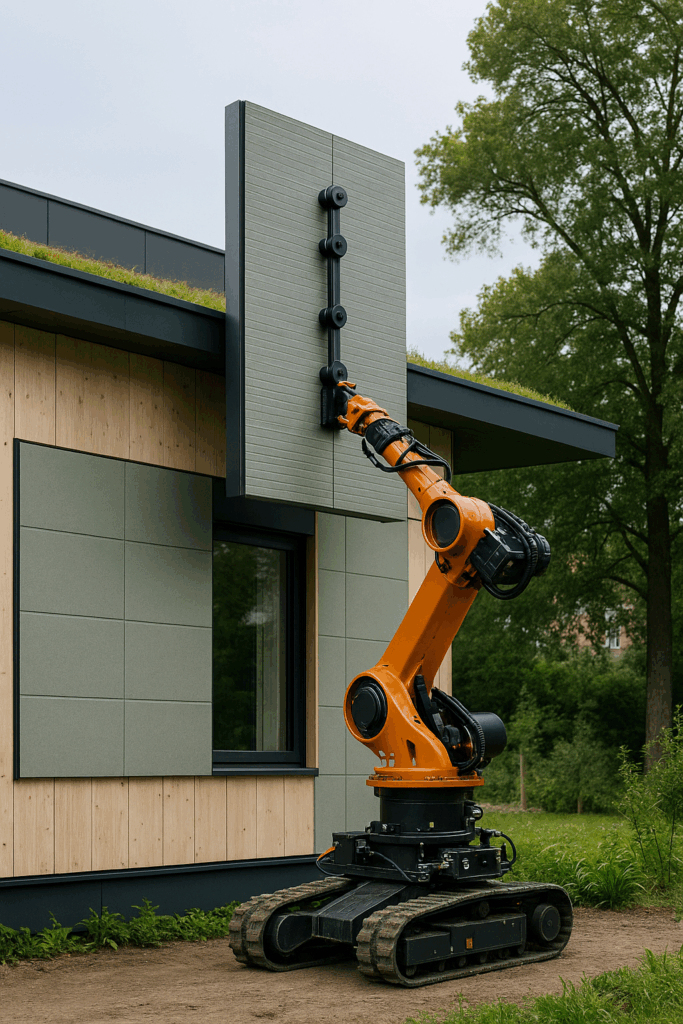

The challenge isn’t just one thing, but it’s a mix of several pressures combined. On busy job sites, manual work exposes labourers to hazardous conditions, unpredictable environments and repetitive strain. Autonomous vehicles and construction robots can remove people from high-risk tasks, creating safer job sites and reducing the likelihood of serious accidents. At the same time, they help ease growing labour shortages across Europe. For example, bricklaying robots can lay up to 300 bricks per hour, which is roughly four times faster than a human mason – allowing teams to redirect skilled workers to higher-value tasks instead of repetitive manual work.

European policymakers recognise the potential of autonomous construction – and this recognition is now translating into funding programmes. The Horizon Europe call on “Robotic Construction, Renovation and Maintenance” sets ambitious expectations: reducing on-site construction time (in some cases by up to 40%), cutting errors and waste, improving resource efficiency, lowering costs, and decreasing greenhouse gas emissions. In practical terms, the call encourages the use of robotic systems, including 3D printing, to automate surveying, lifting and assembly tasks, and to support workers through exoskeletons and assistive devices.

At the more experimental end, the EIC Pathfinder Challenge calls for radical, multi-robot solutions and a shift away from traditional heavy machinery toward modular, digital construction with off-site fabrication and on-site assembly. This isn’t just policy language anymore, but it reflects a genuine shift in how Europe sees its future building methods.

Together, these initiatives make one thing clear: robotics must become part of everyday building operations – a shift that is already accelerating Europe’s move toward digital, low-carbon autonomous construction.

Real‑World Examples: Robots Building Faster and Greener

There are numerous examples of how robots can be used for autonomous construction to optimize building across Europe. Below are a few practical cases that show how robotics is already making construction faster, safer and more sustainable. These aren’t far-off prototypes, but they are being tested or deployed on real sites today.

- Worker‑Augmenting Exoskeletons: Not all robots replace human labour – some augment it. Exoskeletons have been shown to support the lower back, delay fatigue and help prevent long-term injuries common in physical trades. Academic research finds that industrial exoskeletons improve gait efficiency, reduce muscle activation and lower musculoskeletal strain. These wearable systems reflect Europe’s emphasis on human-centric automation – robotics that support workers rather than replace them.

- 3D‑Printed Housing: In pilot projects across Europe, 3D-printed Housing has been shown to be roughly 35-40% faster than traditional construction, with shorter lead times, lower costs and reduced material use, while enabling digital-twin-based quality monitoring. These benefits align with Europe’s sustainability goals and help address the housing crisis without compromising on quality.

- Autonomous Heavy Equipment and Prefabrication: In one European field trial, an autonomous soil compactor with automated steering delivered substantial gains, which is about 30% faster compaction, around 25–27% lower fuel consumption, and roughly seven tonnes of CO₂ savings. It also demonstrated potential labour savings of up to 40%. Electrically powered autonomous construction equipment further reduces greenhouse gas emissions compared with diesel machinery, helping contractors meet EU climate targets.

- Off‑site prefabrication: Industrial robots in off-site prefabrication facilities achieve high precision and consistent quality control, while reducing labour requirements, which is something difficult to guarantee on busy job sites. Bricklaying robots, as noted, can boost productivity fourfold, even in demanding conditions. Surveys show that nearly two-thirds of contractors already use robotics for monitoring or labour tasks; for example, 35% use autonomous heavy equipment, and 6% use prefabrication robotics. The global construction robotics market, valued at about €145 million in 2022, is expected to reach around €660-670 million by 2032.

Toward a Greener Construction Industry

Autonomous construction robots not only boost productivity and safety, but they also make construction more sustainable. Automation reduces waste by ensuring materials are placed precisely, while 3D printing uses only the concrete required for each layer. In field trials, automation-assisted vehicles have shown fuel savings of around 25-27% and roughly 10 tonnes of carbon reductions, depending on site conditions. Electric autonomous equipment further cuts greenhouse gas emissions, and advanced sensors enable predictive maintenance that prevents failures and extends asset life. Taken together, these improvements help bring everyday construction practices closer to the EU’s Green Deal and net-zero ambitions.

Conclusion: Building Europe’s Future Together

Autonomous construction robots are no longer science fiction. Across Europe, robots are printing houses, laying bricks, steering heavy machinery and assisting workers. The results are tangible: faster builds, fewer injuries, lower emissions and reduced costs. Europe’s construction sector stands at a pivotal moment. By embracing robotics and partnering with innovators, it can deliver the sustainable, high-quality buildings the continent needs.

Europe’s construction future will be smarter, safer and more human-centric, powered by robotics that support people rather than replace them. That is the future we work toward every day at Robivon.

Smart farming in Europe includes drones mapping weeds, weed elimination with lasers and machine-vision models distinguishing crops from weeds.

Robivon – Engineering Europe’s autonomous future